Transforming fashion: The role of cobots in manufacturing

Table of contents

Transforming fashion: The role of cobots in manufacturing

In the world of the fashion industry, efficiency and precision are crucial for staying competitive. Cobots, or collaborative robots, are becoming instrumental in reshaping how fashion manufacturing operates by automating tasks traditionally performed by humans. This integration of cobots in manufacturing is revolutionizing processes such as fabric cutting, garment assembly, and packaging. By working alongside human operators, these robots enhance productivity and reduce human error, making them ideal assets for fashion companies aiming to optimize their operations.

Cobots in fabric cutting

One of the most significant applications of cobots in manufacturing within the fashion industry is in fabric cutting. Traditionally, this process is labor-intensive, requiring skilled workers to ensure accuracy and efficiency. Cobots, however, are equipped with advanced sensors and precise cutting tools that allow them to handle intricate cutting tasks with high precision, minimizing material waste and reducing the time required to prepare fabrics for assembly.

Cobots’ ability to consistently follow precise cutting patterns ensures that each fabric piece is cut accurately, maintaining consistency across production batches. This automation not only speeds up the process but also enhances the overall quality of the products, supporting fashion companies in maintaining high production standards.

Garment assembly with cobots

The assembly of garments is another area where cobots in manufacturing shine. In fashion manufacturing, assembling pieces of fabric into a finished garment involves numerous tasks that require dexterity and care. Cobots can assist by handling repetitive tasks such as stitching and finishing work. Their ability to perform these tasks with accuracy and reliability ensures a consistent quality across all pieces produced.

Moreover, cobots are designed to work collaboratively with human workers, taking on monotonous tasks and allowing humans to focus on more intricate and creative aspects of garment design and production. This partnership enhances productivity by efficiently utilizing both human creativity and robotic precision.

Packaging and efficiency gains

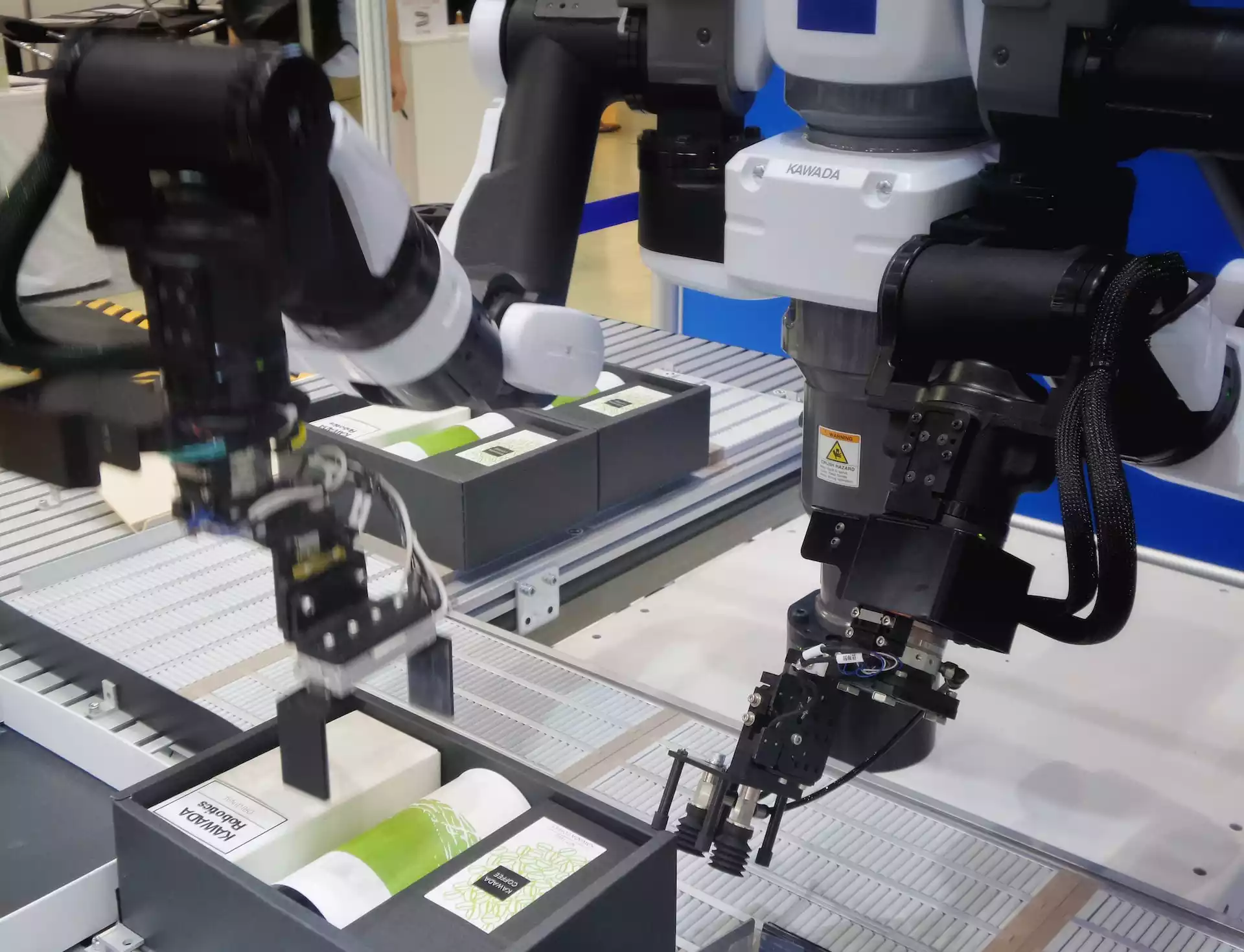

In the final stages of fashion manufacturing, cobots play a major role in packaging the finished products. Their ability to handle goods gently and accurately ensures that garments are packaged correctly without damage. The automation of packaging processes speeds up production workflows and reduces the risk of errors, ensuring that products are ready for distribution quickly.

The incorporation of cobots in manufacturing workflows enables fashion brands to streamline operations, enhancing overall productivity while maintaining high quality.

Safety and collaboration

One of the remarkable features of cobots is their ability to work safely alongside humans. They are designed with advanced safety features, including force-limiting sensors and automatic stop capabilities, which allow them to detect and avoid human contact. This ensures that workers can safely interact with cobots without risking injury, fostering a collaborative work environment.

The flexibility of cobots allows them to be easily reprogrammed and adapted to different tasks, making them particularly valuable in the dynamic world of fashion manufacturing where production lines often change. Their adaptability means that they can quickly switch between tasks, meeting the fast-paced demands of modern fashion production.

Reducing human error

Human error is a significant concern in manufacturing, particularly in industries such as fashion where precision is paramount. Cobots in manufacturing greatly reduce the likelihood of errors by performing tasks with high accuracy and repeatability. This reliability contributes to improved product quality and consistency, essential for maintaining brand reputation in the competitive fashion market.

Advantages for fashion companies

For fashion companies, incorporating cobots in manufacturing offers a multitude of advantages:

- Efficiency improvement: Cobots handle repetitive and time-consuming tasks, allowing operations to run more smoothly and at a faster pace.

- Cost savings: Automation reduces the need for extensive manual labor, cutting down operational costs.

- Enhanced product quality: The precision of cobots ensures high-quality outputs, which are critical in an industry that values craftsmanship and detail.

- Workforce optimization: By automating mundane tasks, workers can focus on more skilled and creative endeavors, driving innovation within the company.

Looking forward: The future of fashion manufacturing

As the fashion industry continues to embrace technological advancements, the role of cobots in manufacturing is poised to expand even further. Enhanced by developments in artificial intelligence and machine learning, future cobots will possess even greater capabilities, making them indispensable in achieving operational excellence. The integration of cobot arms offers fashion manufacturers an opportunity to significantly enhance their automation capabilities. These advanced robotic arms provide unparalleled flexibility and operational dexterity, ensuring a comprehensive and efficient production process.

By adopting a synergistic approach that leverages the unique capabilities of cobot arms, fashion companies can elevate their manufacturing processes, enabling them to quickly respond to market demands and trends. As cobots become more integrated into production lines, their ability to work alongside human talent will drive innovation and efficiency across the industry. AMS, Inc. is committed to supporting fashion manufacturers in this transformative journey, offering cutting-edge cobot solutions designed to optimize production and improve operational efficiency.

Recent posts

Where we are located

Our operations are international, however, our main branch is conveniently located in San Diego, California. It is close to one of the busiest international borders in the world.

We look beyond the scope to surpass your expectations

We understand the importance of retaining a strong working relationship with our customers. AMS provides a niche for everyone through excellent customer care and top-rank products.