Exploring the benefits of the automated palletizing system

Table of contents

Exploring the benefits of the automated palletizing system

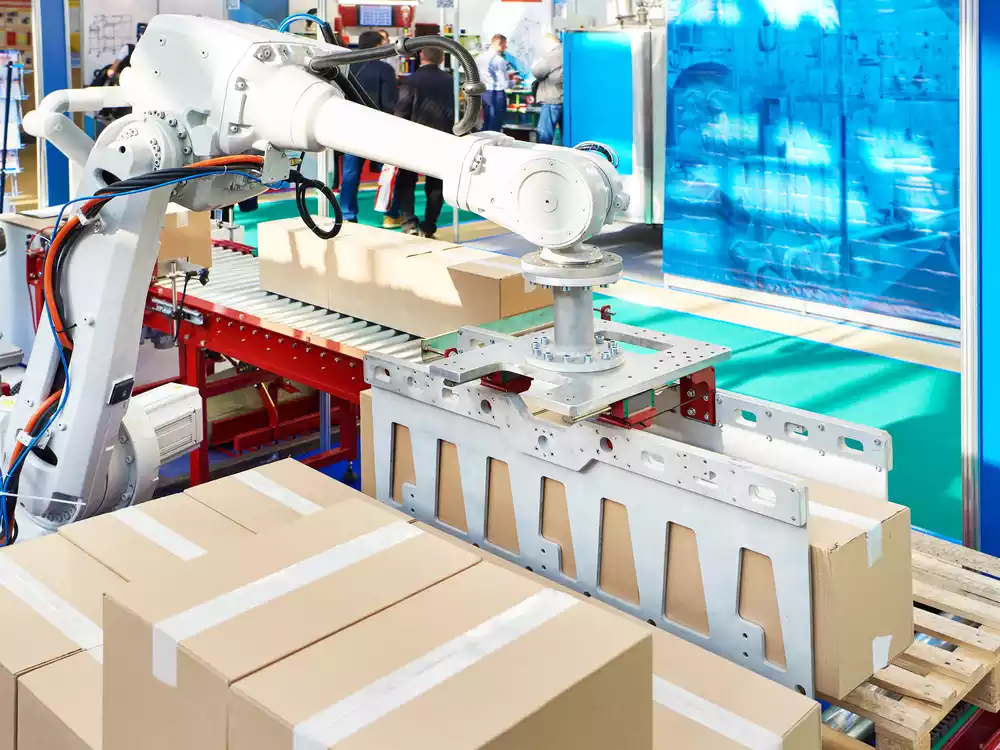

In modern industrial environments, efficiency and accuracy are paramount for maintaining competitiveness and reducing operational costs. An automated palletizing system offers a cutting-edge solution to streamline material handling processes. By integrating advanced technologies and innovative features, these systems provide numerous advantages that enhance productivity and minimize human intervention.

Advanced programming software

One of the standout features of an automated palletizing system is its advanced programming software, which sets it apart in the realm of industrial automation. This sophisticated software is designed to offer unparalleled customization and flexibility, enabling the automated palletizing system to adapt seamlessly to different product types and pallet configurations. By leveraging this feature, facilities can enjoy a level of adaptability that is crucial in today’s fast-paced manufacturing environments.

The intuitive programming interfaces included within the software allow operators to easily adjust parameters and set up new patterns, ensuring that the automated palletizing system can accommodate changing production demands swiftly and efficiently. This feature is particularly beneficial for industries that experience frequent shifts in product lines or seasonal variations in production volumes. By empowering operators with the tools to quickly reconfigure the system, the software helps maintain high throughput levels and facilitates smooth transitions between different product lines.

Moreover, this advanced software supports integration with other automated processes, further enhancing the overall productivity of the facility. It allows for coordinated operations across different stages of production and packaging, ensuring that every aspect of the workflow is optimized for efficiency. As a result, businesses can reduce manual intervention, minimize downtime, and sustain an uninterrupted workflow, ultimately leading to increased profitability and competitiveness in the market.

Complete machine control

An automated palletizing system offers comprehensive machine control directly from its user-friendly interface, ensuring seamless operation and management of the palletizing process. Through this centralized system, operators gain access to all necessary commands and adjustments at their fingertips. This convenience empowers them to oversee every detail of the palletizing tasks with exceptional precision, ensuring that each operation is executed flawlessly.

The intuitive interface of the automated palletizing system allows for quick adaptations and modifications, minimizing setup and transition times between tasks. With the ability to promptly adjust settings and rectify any issues, operators can ensure that every aspect of the operation is optimized for peak speed and accuracy. This level of control supports efficient workflows, reducing the potential for errors and enhancing overall productivity.

Moreover, having complete control over the system enables operators to monitor key performance indicators and operational metrics in real-time. This visibility allows for proactive management of the palletizing process, facilitating timely interventions and adjustments that maintain high standards of efficiency and output quality. As a result, facilities using an automated palletizing system can achieve more reliable and streamlined operations, contributing to a competitive edge in their respective markets.

Pre-programmed patterns

A notable advantage of the automated palletizing system is its incorporation of pre-programmed pallet patterns. These ready-to-use templates enable operators to swiftly execute complex stacking arrangements without the need for manual calculations or intricate planning. By leveraging these pre-configured patterns, the system ensures that each pallet is assembled with optimal stability and space utilization, which is vital for the safe transport and efficient storage of goods.

The inclusion of pre-programmed patterns significantly reduces the likelihood of human error during the palletizing process, enhancing the overall reliability and consistency of operations. This precision not only improves the safety and integrity of the load but also streamlines workflow, allowing operators to focus on other essential tasks. By minimizing manual intervention, the automated palletizing system enhances productivity and supports a smooth, error-free operation.

Real-time monitoring

Real-time monitoring is a pivotal feature of the automated palletizing system, providing managers and operators with comprehensive oversight of the entire palletizing process. This capability allows them to track inputs and outputs efficiently, offering a clear view of inventory levels and enabling the identification of potential bottlenecks before they affect operations.

Access to real-time operational data empowers teams to engage in proactive management, allowing for informed decision-making and timely interventions that maintain optimal efficiency. With the ability to monitor key performance metrics as they unfold, facilities can ensure that their automated palletizing system operates at peak performance, reducing downtime and enhancing overall productivity.

Error diagnosis and HMI

The inclusion of an intuitive Human-Machine Interface (HMI) simplifies the management of an automated palletizing system. This user-friendly interface enables operators to diagnose and address errors swiftly, minimizing downtime and ensuring continuous productivity. The ability to quickly troubleshoot and resolve issues reduces reliance on specialized technical personnel and enhances overall system reliability.

Efficiency and error reduction

The deployment of an automated palletizing system significantly boosts efficiency by reducing manual handling and streamlining processes. The system’s precision reduces the occurrence of stacking errors, which commonly lead to product damage and delays. By automating these tasks, companies can achieve consistent outcomes while reducing the labor cost associated with manual palletizing. This automation also alleviates the physical strain on workers, allowing them to focus on more strategic, value-adding activities.

Minimizing human intervention

By leveraging the capabilities of an automated palletizing system, facilities can minimize the extent of human intervention required in routine material handling tasks. This shift not only reduces labor costs but also mitigates risks associated with human error. The system’s automated nature ensures a higher level of accuracy and efficiency than manual operations, driving improved productivity and operational excellence.

Elevate your operations with palletizing robots from AMS, Inc.

For businesses seeking to enhance their material handling processes, palletizing robots from AMS, Inc. represent a reliable and efficient solution. These robotic systems are designed to seamlessly integrate with your existing operations, delivering the benefits of automation while maintaining flexibility and scalability. With AMS, Inc.’s commitment to innovation and excellence, companies can leverage our automated palletizing systems to achieve higher efficiency, accuracy, and cost-effectiveness in their logistics and warehousing operations.

By investing in the right technology, businesses can transform their palletizing processes, ensuring competitive advantage and operational success in a rapidly evolving market landscape.

Recent posts

Where we are located

Our operations are international, however, our main branch is conveniently located in San Diego, California. It is close to one of the busiest international borders in the world.

We look beyond the scope to surpass your expectations

We understand the importance of retaining a strong working relationship with our customers. AMS provides a niche for everyone through excellent customer care and top-rank products.